Hi guys! I am here to discuss a very new topic, the great contribution of IoT in the supply chain

We will be presenting how IoT is revolutionizing the supply chain and what that means for you. So there's a great deal of excitement around IoT right now. So we're gonna dive right into some trends within the industry and explain how IoT has been come into play and will continue to completely alter the supply chain.

So let's go ahead and get started. So we're going over a brief overview of what we'll be talking about today, I'll go into the history a little bit about IoT and explain the term.

And then we'll talk about some prior challenges. So 87%, this is the percentage of people according to the liquidity groups, most recent study, that before the survey, did not know the term IoT. So if you're out there today, and you're thinking, I don't know what IoT is, well, don't worry, because you are part of the majority here.

Also try: Everything you need to know about IoT?

And so what we're able to do is provide you a lot of information on IoT. And I'm hoping to get to that here today. So there are plenty of people out there who work in and around or have a passion for technology.

Introduction:

And for those who forget that IoT is not as commonly known in the industry as, as some of you may know. So IoT is what we planned to present today and to provide you with a little bit more information.

So the term is 19 years old. For a term being close to two decades old, you'd think that there'd be a clear cut definition for what IoT is, unfortunately, there's not.

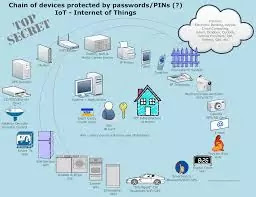

But one definition that our group has come to appreciate is that from Vodafone IoT barometer, and we define that as a system that connects devices to the internet, turning them into intelligent assets that can communicate.

So basically, to break that down for you. What we have are sensors that are added to everyday devices, those sensors collect data, and that data is sent back by way of the internet to allow people and machines to communicate.

Must read: How to make a career in IoT?

So right about the time that cell phones came out, became very popular and mainstream. That's what we're looking at as far as the timeframe. So it's how long the term has been known. But the concept has been around for much longer

Advantages of implementing IoT in the supply chain:

And there are three kinds of key areas that I want to point because, when we want to know about something to adapt it, we search about its pros and cons.

So the first is going to be managed, both of labor and equipment, the second is going to be on maintenance, and then the third is going to be on safety.

Labor:

So starting with labor, I think it's safe to say that labor is a pretty big headache for a lot of people right now, labor is very expensive, it's very hard to find, and then perhaps even harder to hold on to.

Must read: What is the Internet of Things| How IoT helps businesses| Why should you care about it!

And so with these challenges with having labor, we want to make sure that we are getting as much out of the operators or the employees that we do have. And we are looking to IoT to help us with that.

So within a warehousing function, kind of our major functions such as picking or put away, kind of the most common technology we have seen, and we still see is using RF technology, where you are scanning at the start of a task and scanning at the end of the task.

And that way, you're confirming that tasks are complete. And then also you're able to track productivity from your operators.

But this technology is limited because it doesn't tell us really what happens between point A and point B. So if it took an operator, 10 seconds to make, or 10 minutes to make a pic, you know, you can't go back into the data and say, Well, what happened there.

And so with IoT, we have the capability now with Bluetooth networks and cellular networks, where we can track where our operators, our employees are in the facility. So I think that you know, where we are heading.

And so not only is it kind of a way to hold employees more accountable, because they know that we can look back and see what they're doing. So we're able to utilize our labor a little better.

Another way is so this is data that we're collecting in terms of the productivity and the transactions we're doing. All of that data is being fed to one centralized area. And so one thing that IoT is doing now is it is trying to Take data, the raw data, and do a lot of that heavy lifting for you.

Must read: How to make a Career in IoT?

So that it's going to supply you charts, graphs that are automatically generated in terms of labor productivity, so that if you want to change a certain strategy on Monday, you know, you would see the effects from your productivity through those charts that are automatically generated.

So you can get a lot quicker feedback in terms of how your operators are working. And then jumping to equipment management, material handling equipment is quite expensive. But also, it's necessary, it's kind of hard to, to get away without it.

And so we're seeing IoT play a key role in trying to maximize the performance of our material handling equipment, both from a kind of fully automatic automated technology and then also from a more manual technology.

So today, and through this week, if you've been walking around some concern, I'm sure you've seen a couple of AGVs (Automated Guided Vehicle) seems like AGVSs are everywhere here this year.

AGVs are becoming more and more possible because of IoT technology, the number of sensors required on AGVs, to make them safe with humans, as well to have the vision systems to pick products without bumping into things.

Also read: What are the Careers in IoT? Internet of Things and its applications

That's all being driven by advancements in our sensor technology. And then also, we're able to have large fleets of AGVs, because we can have them connected, through the internet, either communicating with each other or communicating through kind of a central controller so that we can have a large fleet work effectively kind of as a team, so they can choose the tasks to perform based off of their current location.

Maintenance:

The piece on maintenance that we wanted to talk about is kind of on the upgrades, and how we were trying to more future proof your systems, it's kind of a hot word, nowadays is future proof.

And so with all of these systems being connected to the internet, we can push upgrades, patches, any type of fixes that are on a software standpoint, wirelessly, either through the original equipment manufacturer, or they can provide it to us, we can do it on our own time.

And that's kind of a hot item right now with your smart cars. So when you plug them in at night, there's a manufacturer that can run an update. So that next morning, when you get in your car, it's an improved car.

And so the nice thing about these automatic upgrades is that you can do them during off-shift hours where you have maybe no one in the facility, or maybe just one person, your facility, watching it and Manning it.

And so it's not going to interrupt your operation by having it during off shift. Another piece on maintenance we want to talk about is that not only is the equipment communicating to you its health, but it's communicating that health to the equipment manufacturer as well.

So they're getting really useful information on the performance of their equipment based on the characteristics of their end-user so they can identify trends in the failures that are occurring, and understand where are the weakest points in their systems.

And that can be the key areas where they devote more engineering time to improve. So I think we'll see moving forward, you know, just quicker responses on improving their equipment.

Safety:

And then kind of the final topic we want to cover is safety. And so speaking on material handling equipment collision at first. So in 2015, OSHA posted an article saying that every year there are approximately 100,000 us injuries that are related to forklift activity, which is quite high.

Must Read: How IoT is revolutionizing the supply chain?

So if we assume that that was one injury per forklift, that would mean 11% of all forklifts in the US would be involved in some type of worker injury.

So that's, that's pretty high. And we were looking to IoT to help bring that down.

And with trucks, there have been some capabilities in detecting collisions for a while. So there are sensors on for trucks that can detect when a collision occurs. And also who is logged into that for the truck when that collision occurs.

But we don't have a clear and easy way to identify that picture and to automate, automate the storage of the information.

If you go into a warehouse and talk to someone that has been in that warehouse for 10 or 15 years that could tell you where the most dangerous parts are in your facility based on experience, but you know, any new employee, they're not going to understand where those kind of hot areas are.

In so with this information, we can collect information on where those collisions are occurring.

And we can kind of going back to those automated reporting automated generation of charts and heat maps, we can create more of a heat map of where are the most dangerous areas in our facility, and we can plan around those by changing the pic pass or just planning the routing a little more effectively.

People know that the standard practice of honking when you're going into an intersection, but again, that's to your operators.

But to do that, this takes that work kind of out of their thinking a little bit more and automates, it ensures that it's truly being done.

And then the last piece of safety is kind of we touched on a little bit, but want to talk a little bit more on wearables that employees can wear to track, real-time their health. And so we've seen these things to be pretty popular in the fitness industry.

For several years now tracking the number of steps you take your heart rate across the day, how much energy you're exerting.

Also read: How to Make a Career in IoT?

I think this is going to become more of an application in warehousing to better fit, or better understand your employee's requirements in terms of, you know, what is the frequency that we need to give these operators breaks?

And how long should those breaks be based on the function they're performing? A lot of times right now, we're giving operators the same breaks break schedule, regardless of function.

So if they're on a piece of material handling equipment versus doing a lot of walking, their break schedule may need to differ. And we can look at how their energy being exerted across time can play into that.

Another thing is that it can, it can look into your productivity a little more, too. So one way to understand if a new slotting method is more effective is how many steps is your operator doing and your old method versus your new method.

So it gives you more visibility into the health of your employees to make sure that they are safe from a health standpoint, especially because they are spending so much time working at your facility in a day.

And a lot of tasks in the warehouse are pretty manually intensive. So it's just looking out for your employees. But that's about all we had for you guys today. If you have any questions, we're gonna open them up to you guys for now.

Credit: Bastian Solutions

Link: How IoT is revolutionizing the supply chain?

Also read: How IoT is revolutionizing the lives of people?

Conclusion:

As we have talked very much and you will be bored If I say much now so as a conclusion, I will say there will be a new IoT era which will take off today's technology. So, Get ready to deep dive into IoT.

Also

So a lot of discussions that we had today were around assets and tracking of assets and how that plays into IoT.

But It's not the end! We will have more interesting sessions like this. So, stay tuned!

Thanks for sharing this great information admin!

ReplyDeleteAll people totally agree with your statement "There will be a new IoT era which will take off today's technology". IoT data platform helps companies rapidly scale their business while reducing operational costs.